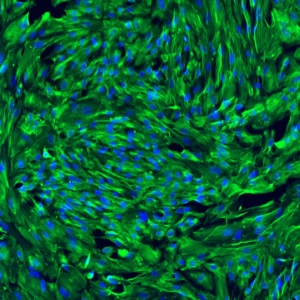

Custom iPSC Differentiation

Our team of stem cell experts specializes in developing tailored protocols to produce virtually any cell type you require.

Our quality-by-design methodology ensures rigorous monitoring and control at every stage, from the initial banking of hiPSCs to the intricate process of directing their differentiation into mature, functional cell types.

Whether you need higher purity, improved functionality, or large-scale production, our customized solutions are designed to meet your specific needs. With state-of-the-art facilities and a deep commitment to quality, we ensure reliable generation of the desired cell populations, enabling you to unlock new avenues in disease modeling, drug discovery, and regenerative medicine research.

Sample Business Cases

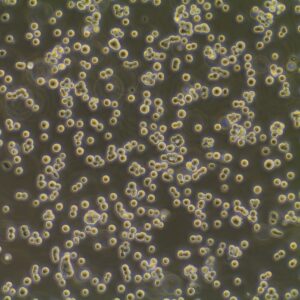

Sample Case 1: Disease Modeling

Custom-differentiated into HPCs the iPSCs of a company’s proprietary line. The company had failed numerous times to differentiate its iPSCs into HPCs, so Trailhead’s engagement saved time and money and allowed the company to meet internal deadlines.

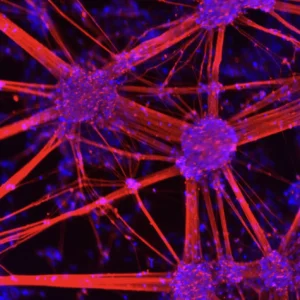

Sample Case 2: 3D Bioprinting

Replaced much more expensive, less accurate (tumor/MIN6) cells for a 3D bioprinting company with superior biological construct (beta cells) for the company’s research. Trailhead beta cells were more affordable, especially at high volumes, than the less-desirable tumor cells.

What This Partnership Entails

Phase I: Onboarding

Our first order of business during the onboarding process is to assign you a project manager or team lead to coordinate activities, facilitate communication, and serve as the primary liaison between you and our team. Communication is one of our top priorities so that we can ensure your satisfaction with any cells delivered to you.

Other features of the onboarding process include…

- Defining expectations of project goals, timelines, and deliverables

- Setting differentiation parameters (i.e. cell type, target lineage, differentiation protocol, culture conditions, and characterization methods)

- Define timelines for Phase II, III, and IV

- Define potential setbacks and outline appropriate measures to correct the problem.

Please note that these are general guidelines, and specific details may vary based on the project’s unique requirements and organizational practices.

Phase II: Expand and Differentiate

We will begin to expand your iPSC lines as soon as they arrive at our facilities. The first step of expansion is to perform quality control tests of all incoming iPSC lines.

As soon as the cells clear the quality control tests, expansion begins. Once the expansion of your chosen iPSC lines is complete, our team will begin to differentiate the cells to your chosen specifications.

Throughout the processes, your assigned representative will keep you informed about critical milestones. This transparent communication ensures that the final cell product meets your exact requirements.

Moreover, we welcome your input and feedback, as your insights can help refine our approach and drive continuous improvement. Our team is committed to building a strong working relationship, where open dialogue and clear expectations are prioritized.

Phase III: QC of Differentiated Cells

During the third phase of our differentiation service, our team performs comprehensive assay analysis to thoroughly characterize the differentiated cell populations. We profile gene and protein expression, conduct functional assays, and assess purity.

Additionally, we run cryo-preservation simulation tests to evaluate if the cells maintain survivability and critical characteristics after freezing and thawing. Only cell populations that meet all target profile specifications and pass the cryo-preservation simulation tests are featured in the following reports, ensuring we deliver high-quality, fit-for-purpose differentiated cells.

Once we complete all the assays, we share detailed reports with you. In these reports, we provide transparency into the raw data, our findings, and our interpretations of the results. Based on the results, together we determine whether the cells meet the predefined target profile in terms of identity, functionality, and desired properties.

Phase IV: Delivery of Final Product

We prepare the differentiated cell populations for delivery according to customer specifications. Our team packages the cells in appropriate cryogenic storage containers with proper labeling and documentation. We include all necessary materials like culture media, reagents, and protocols. We coordinate logistics to ensure secure and timely shipment of the cells and materials. We provide detailed handling and storage instructions.

At Trailhead Biosystems, we understand the importance of preserving valuable cell lines. As part of our exceptional service, we offer complimentary cryogenic storage of your differentiated cells for a limited period after delivery. This allows you to safeguard the cells for backup or future experiments without needing costly storage infrastructure right away. After the free period, we provide options for continued long-term storage at our facility or assist in safely transferring the cells to your preferred location. Our experts follow stringent protocols to maintain cell integrity and viability throughout cryopreservation and storage.